custom mens curved hem t shirt with screen printing | mens tank tops supplier Support OEM and ODM

custom mens curved hem t shirt with screen printing | mens tank tops supplier Support OEM and ODM

| Categories | Screen Printing T-shirts |

|---|---|

| Brand | Fame Garments Men's Casual Clothing Specialist |

| Model | MY-201 |

| Color | custom colors |

| Delivery time for bulk order | 10-30 days after confirming pre-production samples |

| FOB port | Shenzhen or Guangzhou |

| FOB port | FOB Shenzhen/Guangzhou |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Apr 5,2025 |

Item | custom mens curved hem t shirt with screen printing | ||

Features | Customize your logo with screen printing on tshirts | ||

|

Fabric

|

Customize the fabric you like ,cotton or polyester,french terry or fleece etc.

|

||

|

Colors

|

Customize the color you like,we provide color swatch/color book for option.

|

||

|

Sizes

|

Customize the size you like,if you don’t have size chart,we can provide size chart for your reference. |

||

Plate making time | 7-15 days | ||

MOQ | 50-100 pieces per color per design | ||

Shipping time | 4-7 days by express like DHL,UPS, FEDEX, TNT. It will spend at least one month by sea to North America and Europe. | ||

Tags&labels&zippers&buttons | we advise to customize the tags,labels, zippers, buttons after you decide to placethe bulk order from us, it can help you save time and cost. | ||

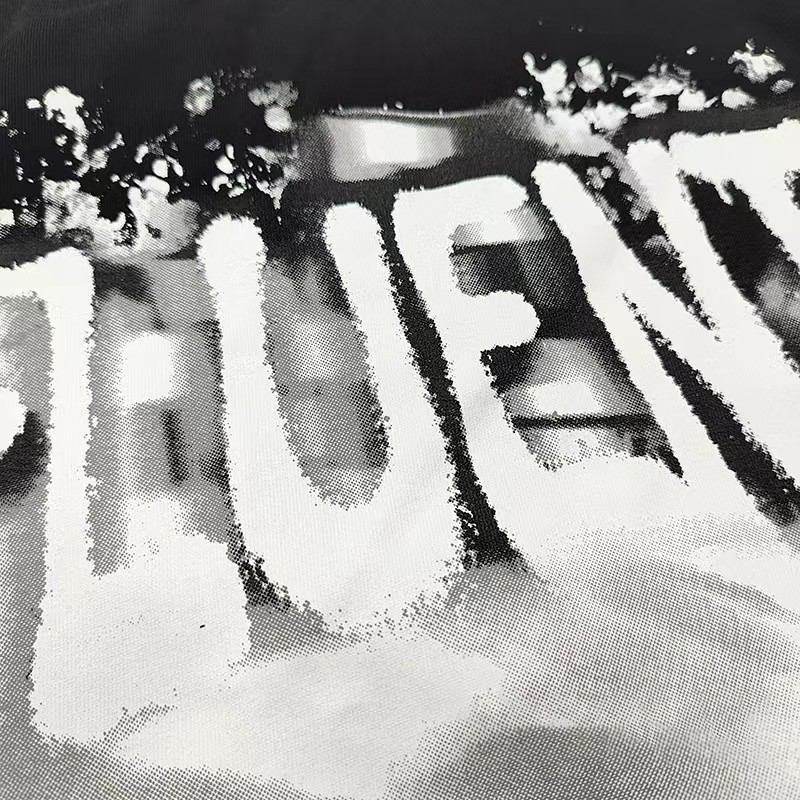

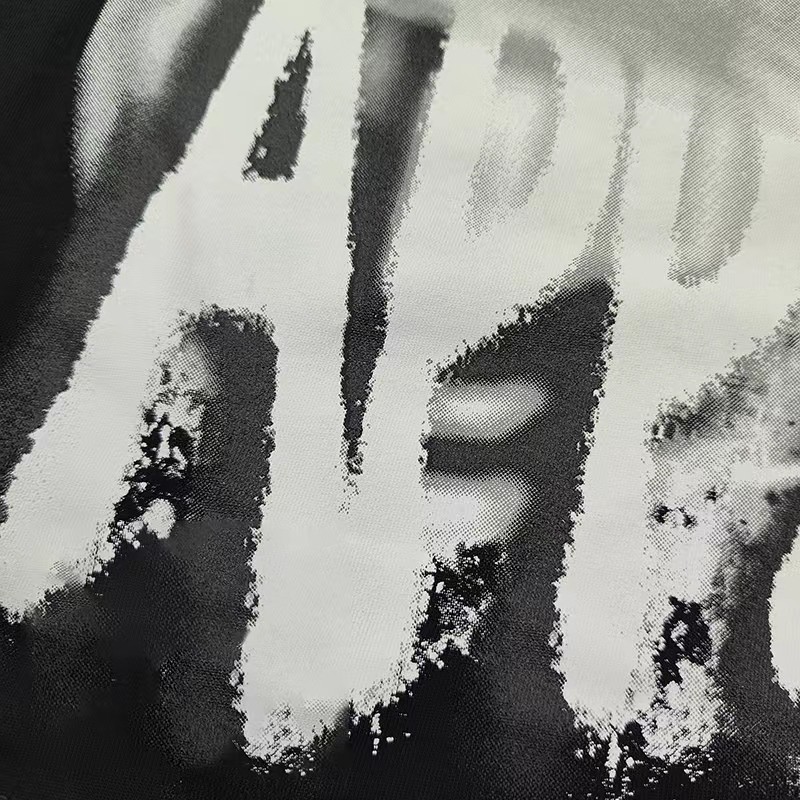

The production process of offset/screen printing technology on the custom mens curved hem t shirt is roughly divided into the following steps:

1. Design: First, it is necessary to design according to the requirements of the printed matter that needs to be made. This can be done by hand drawing or using computer aided design software.

2. Plate making: Next, the design manuscript needs to be converted into a layout. This can be done by using a laser or laser printer to print the design onto a photosensitive resin-coated aluminium sheet.

3. Exposure: Put the prepared layout into the optical exposure machine, and irradiate it with ultraviolet light to solidify it.

4. Plate washing: wash off the uncured photosensitive resin and leave the cured part to form the printing pattern.

5. Printing: Load the produced printing plate into the press, and the printer will transfer the ink to the printing plate, and transfer the printing pattern to the printing medium (such as paper).

6. Post-processing: After printing is completed, post-processing, such as cutting, folding, binding, etc., is required to make the final product.

- Loading...

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content